Characterization of fermentation processes and their bio-based derived products from the food industries – Remote access

Deadline for applications: 15 April 12:00 h

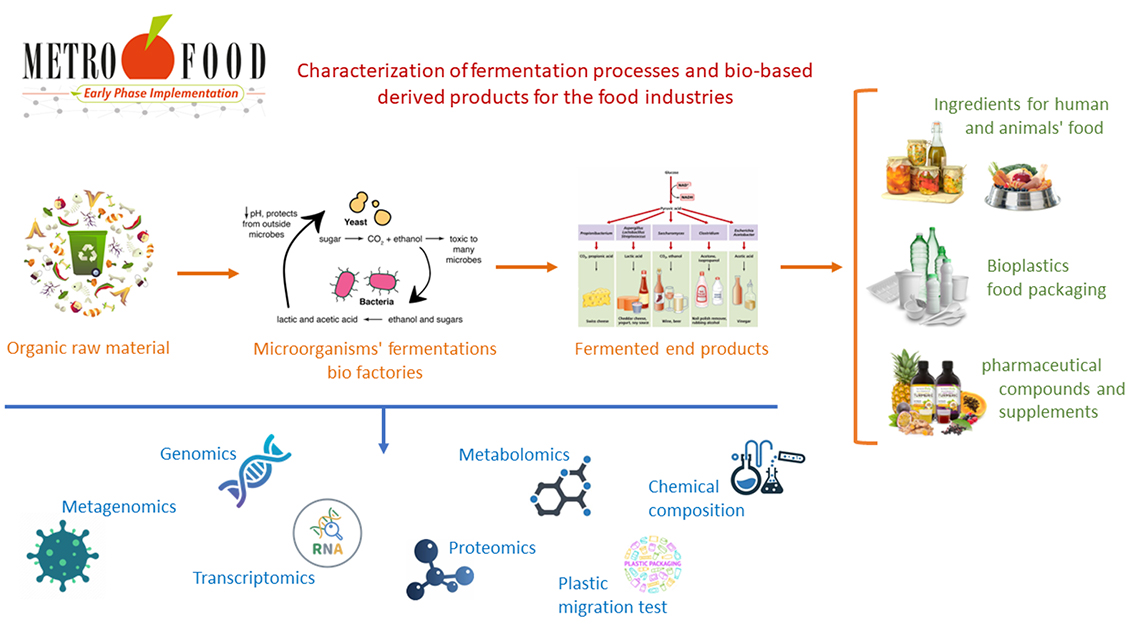

Pilot for the characterisation and safety testing of the complete fermentation process and bio-based products derived from fermentation used in food processing and food packaging.

The service aim is to offer and provide high quality services and demonstrate scientific knowledge and technical solutions to industrial food business operators and scientists on methods to adapt/improve food fermentation process and final food-derived products. The specific services include a consolidated approach encompassing methods in microorganisms' identification (metagenomics), microorganism characterization (metabolomics, metatranscriptomics and metaproteomics), chemical and omics composition (raw material or end-product), contaminants, biopolymers characterisation, migration studies, toxicity analysis, testing bioactivity of end products, etc.

Target users: researchers/academics and companies engaged in food-related fermentation processes: food business operators, food packaging companies, ingredients suppliers, agrobusiness, food inspection agencies/bodies.

Access type: Remote access to the facilities of EUT, IJZSRM, INSA and TUBITAK.

Access mode: Free of charge (with no contribution to eventual shipping costs).

Duration of the service: An average duration of approximately 3 to 8 weeks is foreseen (dependent on the complexity of the analytical request).

Technical details and the feasibility of the projects will have to be discussed with the access managers and the facility managers before project implementation. Direct contact with the responsible managers will be provided.

Background and detailed service information:

Omics technologies and other various analytical techniques such as chemical composition and/or global migration, toxicity, and bioactivity analysis will be employed to characterize fermentative food-related processes. These techniques provide detailed information about the composition, structure, and properties of the raw materials, intermediates, and final products.

Omics analysis offers a holistic and in-depth understanding of the intricate biological events occurring during microbial transformations. Encompasses various high-throughput methodologies, including genomics, transcriptomics, proteomics, metabolomics, and metagenomics, which collectively enable the systematic analysis of genes, RNA transcripts, proteins, metabolites, and microbial communities. In the context of fermentation, these techniques play a pivotal role in unraveling the complex interplay of microorganisms, their genetic expressions, and the metabolic pathways driving the conversion of raw substrates into valuable bio-products. The integration of these omics approaches provides a comprehensive picture, facilitating process optimization, yield enhancement, and the assurance of product safety and quality. The application and benefits of the omics technologies on fermented process are:

Genomics involves the study of the complete set of genes in an organism. Understanding the microorganisms in fermentation processes (such as yeast or bacteria) helps to optimize fermentation conditions, thereby enhancing product yields, and ensuring the desired properties of the bio-products. Technology: Next Generation Sequencing technology (Illumina sequencer, Ion Torrent sequencer, Oxford Nanopore sequencers).

Metagenomics involves the study of the entire microbial community in a given environment. Metagenomics helps to characterize the diversity and dynamics of microbial populations, which is key in fermentation processes. Understanding the microbiome is crucial for maintaining a stable and efficient fermentation process. It aids in the identification of beneficial and detrimental microorganisms, contributing to process control and product safety. Technologies: Shotgun metagenomics, 16S metagenomics, virome sequencing, metabarcoding. Samples cut be all type of DNA or depending on the facility just samples DNA samples extracted from food products (in this case/facility samples must be quantified and evaluated for DNA integrity before shipping). The service can include DNA extraction and quantification and evaluation for DNA integrity.

Transcriptomics and metatranscriptomics focuses on the study of all RNA molecules, including mRNA. It provides insights into gene expression patterns during fermentation, and this helps in understanding how microorganisms respond to different fermentation conditions, identifying key regulatory pathways, and optimizing the production of bio-products. Technologie: RNA-Seq, targeted RNA-Seq, mRNA-Seq, RT-PCR.

Proteomics and metaproteomics involves the study of the entire set of proteins in a biological sample. In the context of fermentation, proteomics can help identify and quantify proteins produced during the process, providing insights into the functional aspects of microorganisms, such as enzyme activities and metabolic pathways, contributing to the optimization of fermentation processes. Technologies: Mass spectrometry-based proteomics (LC-qTOF, LC-QqQ, Orbitrap, MALDI-TOF/TOF) and antibody-based proteomics (Bioplex)

Metabolomics aims to profile and quantify all small-molecule metabolites in a biological system. In fermentation, metabolomics helps track changes in metabolite concentrations over time, providing a holistic view of the metabolic state of microorganisms, helping to optimize fermentation conditions, improve bio-product yields, and ensure product quality. Technologies: Mass spectrometry-based metabolomics with Untargeted and (semi)targeted studies, and also lipidomics, glycomics, fluxomics; MALDI Imaging. NMR-based metabolomics profiling analysis.

Global migration analysis: Evaluation of the conformity of plastic packaging resulting from the use of bio-based products derived from fermentation. This step ensures the safety of the materials developed to prevent the migration of constituents to the food in question and/or ensures that these materials are food-grade and approved for use in contact with food. This service is crucial for developing new biodegradable and active food packaging under sustainability and circular economy principles. Analitical procedures will be made following: 1) Test for Global migration, specific migration test to determinate metals with FAAS; GFAAS and ICP/MS and test for primary aromatic amines. Determination of the Global migration regarding plastic materials and articles intended to come into contact with food is according to the Commission Regulation (EU) No.10/2011 and following the EN 1186-3: 2022 gravimetric method. Migration of the primary aromatic amines from plastic materials and articles intended to come into contact with food simulant is according to the standard method: § 35 LMBG. The laboratory complies with the accreditation criteria for testing laboratories according to the EN 17025:2018, recognized by the Institute for accreditation of the Republic of North Macedonia (IARNM) Certificate No.LТ – 005. And 2) Global Migration trials regarding plastic materials and objects intended to come into contact with food are conducted according to the Commission Regulation (EU) No. 2020/1245 of 3 March 2014, amending Regulation (EU) No. 10/2011. According to regulation, global migration tests for evaporable simulants are carried out according to the material to be analysed. The Laboratory complies with the accreditation criteria for testing laboratories established in NP EN ISO/IEC 17025:2005, recognized by the Portuguese Institute of Accreditation (IPAC), through accreditation certificate nº L0427. Global Migration is performed following the EN1186-1 and EN1186-3 methods.

Chemical composition analysis.

Chemical compositions are valuated though the analytical methodologies to determine lipids, fatty acid profile, vitamins. proteins, sugars (glucose, fructose, sucrose, maltose), general carbohydrates, raw and dietary fiber, organic acids, ash, minerals, salt, energy value, total fat, organic acid, amino acid profile, total phenolic content, total antioxidant activity, starch, count of lactic acid bacteria (isolation, identification and technological characterization of lactic acid bacteria and yeast), pH, total acidity, sterol composition, free fatty acids, in-vitro protein digestibility (PD), phytic acid, tannin contents and heavy metals. Additional offer to chemical composition: texture, viscosity, color and organoleptic analysis.

The selection procedure will take into account: compliance with the technical, scientific and ethical requirements. Requested analyses have to fit into a relevant project aligned to food-related fermentation including by-products evaluation. Requests have to include clearly defined objectives and time-frame in accordance with the provided application form. Special attention will be paid for the presentation of the interest in more than one analytical provided service.

For any information about METROFOOD-RI open calls, please contact: ; for any information about this call, please contact:

This open call is promoted as a part of the METROFOOD-EPI project Funded by the European Union (GA 101130162).