Pilots for food production and integrated analytical services

Deadline for applications: 19 April 12:00 h

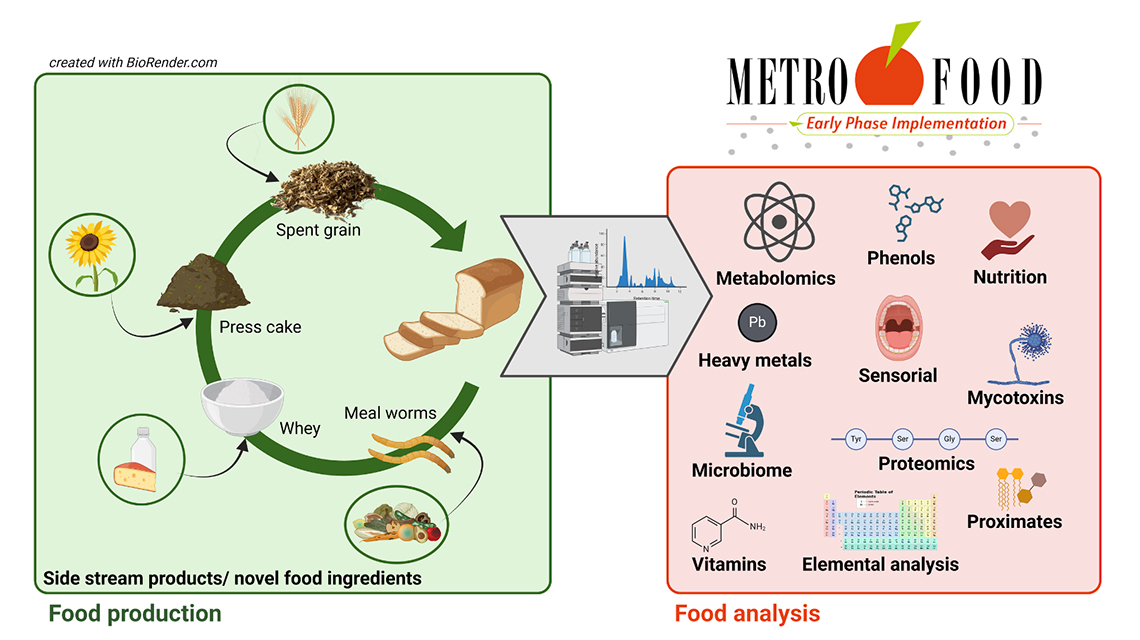

The integrated service with a pre-defined set of grouped combinatorial analytical services and food technologies will involve the use of food by-products (e.g., from cereals) and novel ingredients (e.g., insects) for preparing new food components and products. After having produced and processed new food items or ingredients, the analytical services will be focussed on their sensorial, nutritional, and health-promoting characterization as well as on assessing their safety. Within the framework of sustainability, the project is aimed towards future-oriented applications e.g., circular systems for the reduction of food waste.

Target users: researchers/academics and industrial food business operators.

Access type: Physical + Remote access. Physical access will be provided to the experimental facilities of IBA/CZU and their associated labs; remote access to the analytical laboratories of TUM, ENEA, AUTH, JSI, CZU and IBA will be established.

Access mode: Free of charge (with no contribution to eventual shipping, travel, and subsistence costs). Applicants will have to provide the food by-products that are to be used in the food processing.

Duration of the service: An average duration of approximately 16 weeks (for the practical plant & lab work, excluding data evaluation) is foreseen (dependent on the complexity of the analytical request; to be estimated in detail between the users and the access manager in charge for the service based on the application evaluation results).

Technical details and the feasibility of the projects will have to be discussed with the access managers and the facility managers before project implementation. Direct contact with the responsible managers will be provided.

Background and detailed service information:

The global food system faces unprecedented challenges, including food insecurity, environmental degradation, and climate change. To address these issues, there is a pressing need for a paradigm shift towards sustainable food production and distribution. Insects offer a novel and sustainable food source rich in protein, vitamins, and minerals. Compared to conventional livestock, insect farming requires less resources and produces fewer greenhouse gas emissions. Embracing insect-based foods can diversify food sources, reduce environmental impact, and enhance food security for present and future generations. In addition to finding novel sources for sustainable and nutritious ingredients, the integration of side-stream products as ingredients in circular systems to reduce food waste and production losses harbours an opportunity to increase resource efficiency. Side stream products from food processing are found throughout all agri-food sectors, such as whey from cheese production, press cakes (e.g., sunflower) from oil pressing or spent grains from brewing, each still containing promising amounts of nutrients. Many different stakeholders, from farmers to food manufacturers, could profit from the valorisation of these by-products by including them into processes such as baking. For the development of novel, sustainable food ingredients the technological design should be strongly intertwined with a comprehensive chemico-physical characterisation to enable product safety, usability, as well as transparency for producers and consumers.

Our pilots for food production and integrated analytical services offer two different approaches:

Technological details:

Option 1: Insects as novel food ingredients (CZU)

- Rearing of edible insects (Tenebrio molitor larvae or Acheta domesticus adults) under defined rearing and feeding conditions in insectarium.

- Insect growing parameters (weight, larvae length) evaluation.

- Insect killing and lyophilisation.

Food technological facilities:

- Small scale processing lines (bakery, meat, milk and dairy products) linked to sensory analytical laboratory.

Option 2: Implementation of cereal by-products (bran, germs, straws…) as ingredients (IBA)

- Step: Designing food ingredient or food matrix

- Fermentation/extraction/conditioning (drying, milling) and different technologies can be applied to obtain a good quality product: direct baking process, two phases baking process, three phases bread making process. The fermentation processes can be applied to different types of brans, followed by conditioning steps as drying and milling to obtain a sour ingredient which can be added in the bread dough preparation to increase the acidity, the shelf life, as a natural dough improver; different concepts will be designed. The by-products can be added in different recipes e.g., 2-10% bran in wheat flour; 3-4 types of recipes and technologies will be tested to select the best combination (the higher amount of by-products which can be added in the recipe with a good quality end product); different recipes and technologies will be designed as concepts

- Laboratory tests for recipes and technologies validation: the concepts developed will be tested al laboratory scale (small batches: up to 1 kg)

- Experimental tests for intermediary prototypes (e.g. doughs, meat paste): the intermediary phases in the processing chain (the dough in case the obtaining of bread products) will be analysed for: rheology, acidity, humidity, elasticity, stability.

- Selecting the optimized recipe and technology: the best recipe and technology will be selected (the best dough rheological behaviour, the best quality of the final product-after baking)

- Step: Pilot functionality demonstration:

- Establishing of the technological parameters: temperature, pH, time, pressure etc.: the best recipe and technology selected will be tested at pilot scale (larger batches, few kilos) and the optimal technological parameters will be established.

- Revising the recipes and technologies (if the case): If the results show some negative effects of adding too high amounts of by-products in the product recipe, the recipe is revised/or the technology to obtain a good and acceptable final product quality.

- Shelf-life studies and packaging: Shelf-life studies will be done. The final products will be analysed microbiological and sensorial at each 2-3 days to observe the changes in the quality and the shelf life will be established. The influence of different packaging types (paper, plastic bags with different oxygen barrier permeabilities) on the quality and shelf life of final products will be tested.

- Labelling: a nutritional label model will be designed, with all the necessary information for consumers, in accordance with the legislation

- Specific material consumptions: ingredients consumption/kg end product: after the pilot tests, the specific amounts from each ingredient will be calculated to obtain 1 kg of the final product.

- Step: Industrial test

- First industrial batch: the final recipe/technology will be applied at industrial level to demonstrate its functionality (more than 10 kg batch).

Analytical details:

Basic composition/proximate nutritional characterisation:

- Dry matter

- Ash

- Total fat

- Crude protein content

- Fatty acid profile

- Amino acid profile

- Carbohydrates

- Dietary fibers (soluble, insoluble)

Elemental analysis:

- Macro-, micro- trace- and ultra-trace elements

Metabolic profiling:

- Polar: Amino acids, sugars, organic acids, phenylpropanoids, alkaloids

- Non-polar: isoprenoids, lipids

Contaminants/safety:

- Heavy metals

- Mycotoxins (alternaria, fusarium, aspergillus)

- Microbiological tests (total number of germs)

- Phytic acid

Micronutrients/health promoting compounds/others:

- Vitamin B6, B9 and B12

- (Poly-) phenols

- Antioxidants

- Minerals

- Volatile organic compounds

Sensorial:

- Taste and smell (panel evaluation)

- Texture

- Colour

Nutritional:

- Protein digestibility

- Glycaemic index

The selection procedure will take into account the compliance with the technical, scientific and ethical requirements. Requested analyses have to fit into a project related to food safety and sustainability. The request has to include clearly defined objectives and time-frame. Special attention will be paid for the presentation of the interest in food pilot demonstrator topic and the remote access to different providers of the analytical services.

For any information about METROFOOD-RI open calls, please contact: ; for any information about this call, please contact:

This open call is promoted as a part of the METROFOOD-EPI project Funded by the European Union (GA 101130162).